2Kg 300° Clutch Servo

- $5.80 3+ items

- $5.70 5+ items

- $5.50 10+ items

Introduction

When a servo is operated under complex circumstances such as robot and model, it may get stuck, be burned or damaged due to external forces, which could bother you a lot...

Now DFRobot is launching a series of servos with clutch function and electronic protection that can solve your problems perfectly.

Clutch Function

When the angle of a servo is changed by external forces during normal operation, the servo can automatically reset and continue working through clutch function, which prevents it from being damaged.

Electronic Protection

After being blocked for 5 seconds, the servo will automatically turn off its power to avoid getting burned.

Servo Internal Structure

This servo features large torque, stable performance, accurate running angle and easy to install. The operating voltage is 4.8~6V. When the servo is powered at 6V, its stall torque will exceed 2Kg. There are no limited switches inside the servo so it can rotate smoothly in 360 degrees (manually only). Meanwhile, the servo could operate fluently with minimal power, and you can just supply power to it by normal battery or USB. In addition, users can directly control the servo using servo libraries in Arduino IDE and let it reach a maximum 300 degrees rotation angle within the pulse range of 500-2500μsec.

Mechanical Dimensions

| Selection Guide for Clutch Servo | ||||||

| Model | 6kg 180° | 6kg 300° | 9g 180° | 9g 300° | 2kg 180° | 2kg 300° |

| SKU | SER0051 | SER0057 | SER0049 | SER0053 | SER0050 | SER0056 |

| Operating Voltage | 4.8-6VDC | 4.8-6V DC | 4.8-6V DC | 4.8-6V DC | 4.8-6V DC | 4.8-6V DC |

| Quiescent Current | ≤10mA at 6.0V | ≤10mA at 6.0V | ≤8mA at 6.0V | ≤8mA at 6.0V | ≤8mA at 6.0V | ≤8mA at 6.0V |

| No-load Current | ≤60mA at 6.0V | ≤60mA at 6.0V |

≤50mA at 4.8V

≤60mA at 6.0V

|

≤50mA at 4.8V

≤60mA at 6.0V

|

≤110mA at 4.8V

≤120mA at 6.0V

|

≤110mA at 4.8V

≤120mA at 6.0V

|

| Stall Current | ≤1.65A at 6.0V | ≤1.65A at 6.0V |

≤550mA at 4.8V

≤650mA at 6.0V

|

≤550mA at 4.8V

≤650mA at 6.0V

|

≤700mA at 4.8V

≤800mA at 6.0V

|

≤700mA at 4.8V

≤800mA at 6.0V

|

| Rated Torque | ≥4.4kg.com at 6.0V | ≥4.4kg.com at 6.0V |

≥0.32kgf·cm at 4.8V

≤0.4kgf·cm at 6.0V

|

≥0.32kgf·cm at 4.8V

≤0.4kgf·cm at 6.0V

|

≥0.45kgf·cm at 4.8V

≥0.55kgf·cm at 6.0V

|

≥0.45kgf·cm at 4.8V

≥0.55kgf·cm at 6.0V

|

| Stall Torque | ≥6kg·cm at 6.0V | ≥6kg·cm at 6.0V |

≥1.0kgf·cm at 4.8V

≤1.2kgf·cm at 6.0V

|

≥1.0kgf·cm at 4.8V

≤1.2kgf·cm at 6.0V

|

≥1.6kgf·cm at 4.8V

≥2.0kgf·cm at 6.0V

|

≥1.6kgf·cm at 4.8V

≥2.0kgf·cm at 6.0V

|

| Operating Angle | 180°±10° | 300°±10° | 180°±10° | 300°±10° | 180°±10° | 300°±10° |

| Pulse Width Range | 500~2500μs | 500~2500μs | 500~2500μs | 500~2500μs | 500~2500μs | 500~2500μs |

| Communication Mode | PWM | PWM | PWM | PWM | PWM | PWM |

Specification

- Operating Voltage: 4.8-6V DC

- Static Current: ≤8mA at 6.0V

- No-load Current: ≤110mA at 4.8V

- Stall Current: ≤700mA at 4.8V

- Rated Torque: ≥0.45kgf·cm at 4.8V

- Stall Torque: ≥1.6kgf·cm at4.8V

- Operating Angle: 300°±10°

- Communication Mode: PWM

- Pulse Width Range: 500~2500μs

Projects

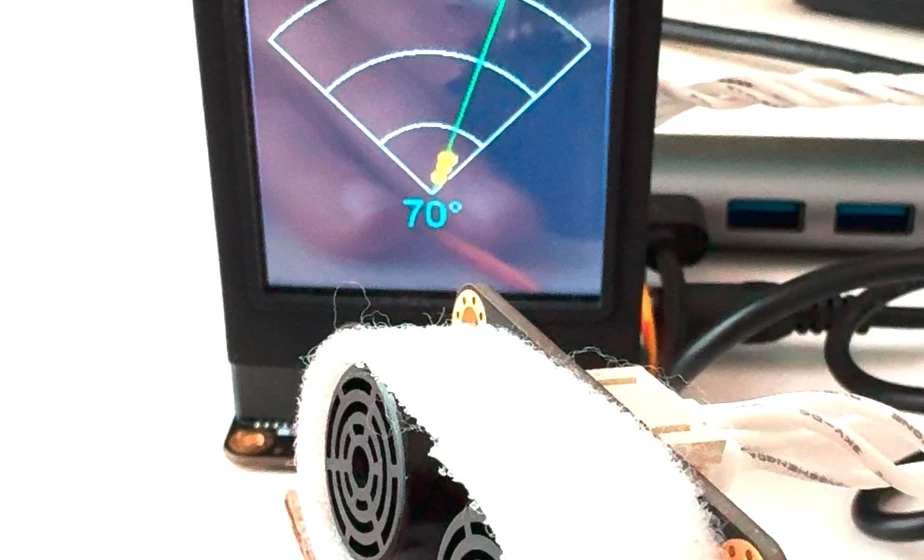

Hi, there! Just got several micro servos (9g180°, 9g300°, 2kg180°, 2Kg 300°). Today I am going to test them, and figure out the differences among them and see where they can be used. Hope this will be helpful for someone who just wants to get a servo like this kind.

Shipping List

Resource

Review

Jan 20, 2025

I love the 300° clutch servos from DFRobot! Use them for different projects since long time.

_150x100.jpg.webp)